Why everyone chooses NAWOO…

Not only do we have our in-house production & assembly line in spacious area of 5000㎡ But we also have over 50+ Cooperative Supplier Chain Network established for more than 16+ years.

This allow us to have comparative advantage over other companies, as we are diversifying our area of business into AI Based Medical, Dental, Bio-Products, Robots, Semi-conductor, Communications with our robust capabilities we focus our motto as to promise our clients with competitive costs, quality proven products & service.

PRODUCTION SITE

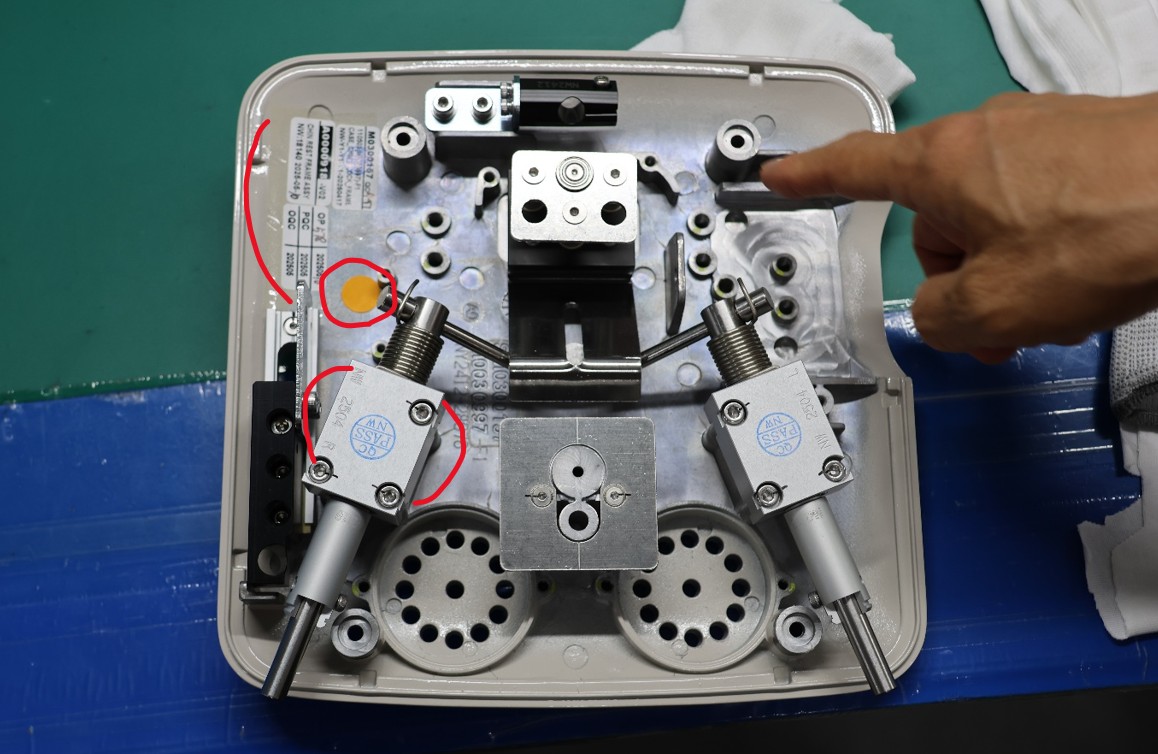

1.MAN & MACHINES

Classified into three 1st floor processing facilities: 8 MCTs / 3 CNC Precision Automatic Lathe (CNC Composite Milling) / 2 TURN MILLs./ 1 Ultrasonic Cleanser and Laser Marker

The quality is based on on on-site inspection by workers and managers once in the morning/afternoon/night to prevent mass defects and monitor tool wear in real time.

2. MATERIAL & METHOD

In accordance with ISO9001 certification (2015 version), NAWOO conducts full inspection (100% inspection) of management items from warehousing materials to import inspection standards, and does its best to ensure quality through LABELING work marked with inspectors for LOT management after inspection. LOT Labeling is a system used to track and inspect batches of raw materials, components, or parts received from suppliers before they enter production. It ensures that only quality-approved materials are used in manufacturing.

We follow the industry standard to mark:

1. Supplier delivery

2. Labeling & Identification

3. Quality Inspection

4. Approval/Rejection

3. Final Packaging check

After all parties are satisfied with goods to be trade, We make sure all products are labelled and ready for shipping, all items are carefully packaged and shipped for delivery

4. Confirmation of goods

After the delivery was completed, we have maintained the relationship by building a cooperative relationship and trust through continuous exchanges to ensure that customers received the product safely.

The system has been established to enable real-time response to external logistics problems that may occur during delivery.